Oxygen Analysis¶

- PIs

Susan Becker

James Swift

- Technicians

Andrew Barna

Robert “Ben” Freiberger

Equipment and Techniques¶

Dissolved oxygen analyses were performed with an SIO/ODF-designed automated oxygen titrator using photometric end-point detection based on the absorption of 365nm wavelength ultra-violet light. The titration of the samples and the data logging were controlled by PC LabView software. Thiosulfate was dispensed by a Dosimat 665 buret driver fitted with a 1.0 ml burette.

ODF used a whole-bottle modified-Winkler titration following the technique of Carpenter [Carpenter1965] with modifications by [Culberson1991] but with higher concentrations of potassium iodate standard (~0.012 N), and thiosulfate solution (~55 g/L).

Pre-made liquid potassium iodate standards and reagent/distilled water blanks were run every day (approximately every 3-4 stations), with samples analysed within 24 hours of the last standard.

Sampling and Data Processing¶

A total of 2947 oxygen measurements were made, of which 2937 were niskin samples and 10 were underway samples. Niskin samples were collected soon after the rosette was secured on deck, either from fresh niskins or immediately following CFC sampling.

Nominal 125 mL volume-calibrated biological oxygen demand (BOD) flasks were rinsed 3 times with minimal agitation using a silicone draw tube, then filled and allowed to overflow for at least 3 flask volumes, ensuring no bubbles remained. Pickling reagents MnCl2 and NaI/NaOH (1 mL of each) were added via bottle-top dispensers to fix samples before stoppering. Flasks were shaken twice (10-12 inversions) to assure thorough dispersion of the precipitate - once immediately after drawing and then again after 30-60 minutes.

Sample draw temperatures, measured with an electronic resistance temperature detector (RTD) embedded in the draw tube, were used to calculate umol/kg concentrations, and as a diagnostic check of bottle integrity.

Niskin samples were analysed within 2-12 hours of collection, and the data incorporated into the cruise database. Underway samples were analysed within 96 hours of collection.

Thiosulfate normalities were calculated for each standardisation and corrected to 20°C. The 20°C thiosulfate normalities and blanks were plotted versus time and were reviewed for possible problems, and were subsequently determined to be stable enough that no smoothing was required.

Volumetric Calibration¶

Oxygen flask volumes were determined gravimetrically with degassed deionised water to determine flask volumes at ODF’s chemistry laboratory. This is done once before using flasks for the first time and periodically thereafter when a suspect volume is detected. The 10 mL Dosimat buret used to dispense standard iodate solution was calibrated using the same method.

Standards¶

Liquid potassium iodate standards were prepared in 6 L batches and bottled in sterile glass bottles at ODF’s chemistry laboratory prior to the expedition. The normality of the liquid standard was determined by calculation from weight. The standard was supplied by Alfa Aesar and has a reported purity of 99.4-100.4%. All other reagents were “reagent grade” and were tested for levels of oxidising and reducing impurities prior to use.

Narrative¶

Cruise setup began on March 12th 2021 in Woods Hole, MA, USA.

A 5x batch (4.3L) of MnCl and a 4x (3.5L) batch of NaI/NaOH was made in port so more reagents would not need to be made while underway. Only a 2L of thiosulfate was made and would need to be made at least once more with the anticipated number of samples.

Due to low temperatures in Woods Hole, there was concern that the ODF oxygen standards may have frozen in the shipping container before load started. Good agreement with both the expected normality of a carefully prepared thiosulfate batch and an OSIL oxygen standard alleviated these concerns. The OSIL oxygen standard was run against the usual ODF oxygen standard during the a standardization around station 48. The OSIL standardization followed the same procedure as normal with the exception of using an Eppendorf pipette to dispense the standard.

The need for smoothing thiosulfate normality was considered separately for each thiosulfate batch (2 in total). Smoothing was performed on both batches, the first batch having no trend (averaged), the second batch showing a trend related to temperature control difficulty the ship had as the sea and air temperature warmed. The smoothed final values had differences no more than ±0.3 µmol/kg from the non smoothed values.

No further data updates are expected.

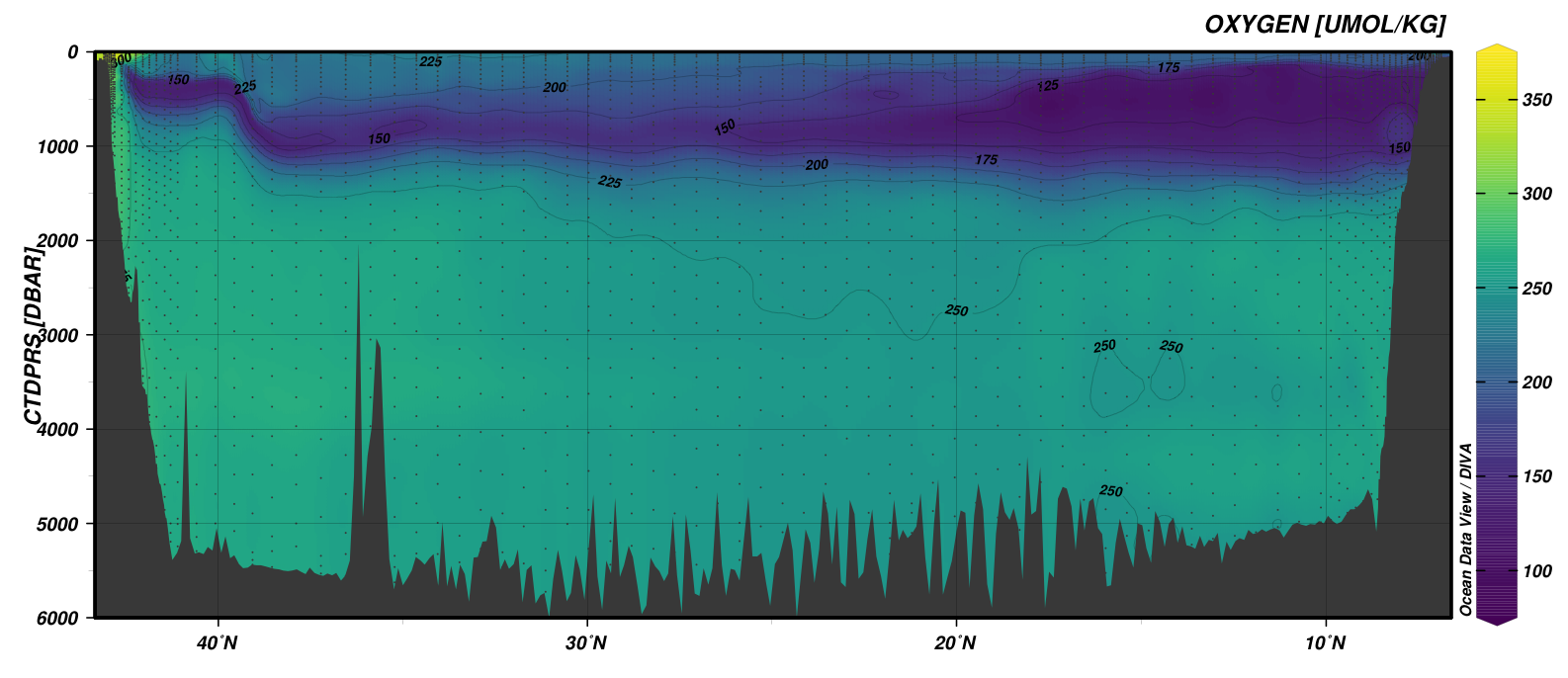

Bottle oxygen data gridded on isopycnals.¶

- Carpenter1965

Carpenter, J. H., “The Chesapeake Bay Institute technique for the Winkler dissolved oxygen method,” Limnology and Oceanography, 10, pp. 141-143 (1965).

- Culberson1991

Culberson, C. H., Knapp, G., Stalcup, M., Williams, R. T., and Zemlyak, F., “A comparison of methods for the deter mination of dissolved oxygen in seawater,” Repor t WHPO 91-2, WOCE Hydrographic Programme Office (Aug 1991).