CTD and Rosette Setup¶

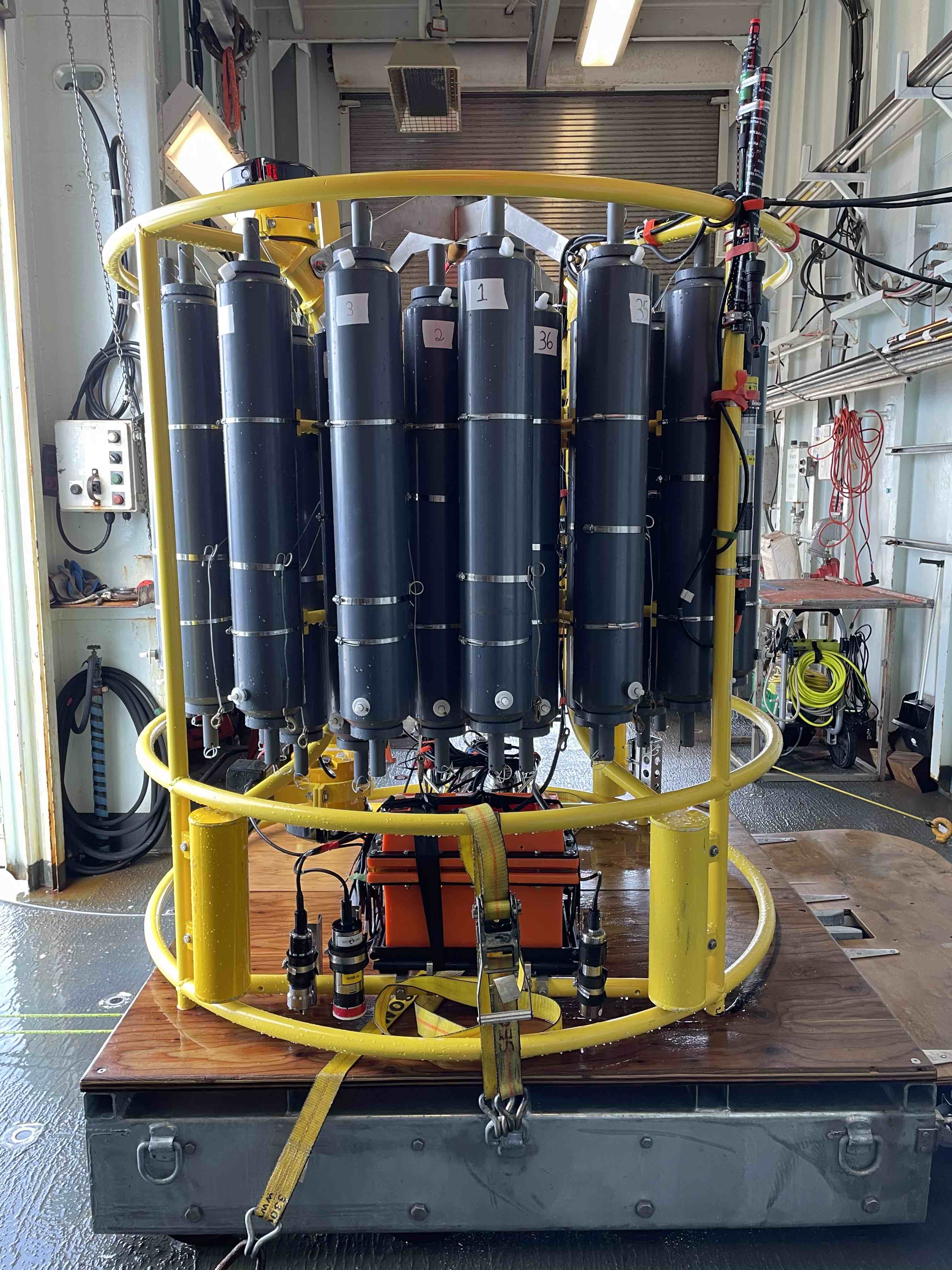

For A20-2021 the new STS 36 place yellow rosette and bottles, built in 2017, were used. The rosette and bottles were built before P06 2017, making this the fifth time this package has been deployed. The bottles were made with new PVC, with new non-baked o-rings and electro-polished steel springs. This represents a change from the past, where on GO-SHIP cruises using ODF equipment before P06 2017 o-rings were baked for 3 days at 100°C at 1-3 Torr in a sweeper gas of hydrogen. Springs used to be painted and Tygon tubing added to the ends to prevent paint wearing away from bottle firing. As on P06 2017 no sample contamination has been noticed by the change in o-rings and springs. The package used on A20-2021 weighs roughly 1500 lbs in air without water, and 2350 lbs in air with water. The package used on A20-2021 weighs roughly 950 lbs in water. In addition to the standard CTDO package on GO-SHIP cruises three chipods, two LADCPs, and one experimental CTD were mounted on the rosette. During the cruise we encountered a handful of problems, most notably noisy altimeter data and bottle firing issues. We describe all of the above in more detail in the sections below.

Underwater Sampling Package¶

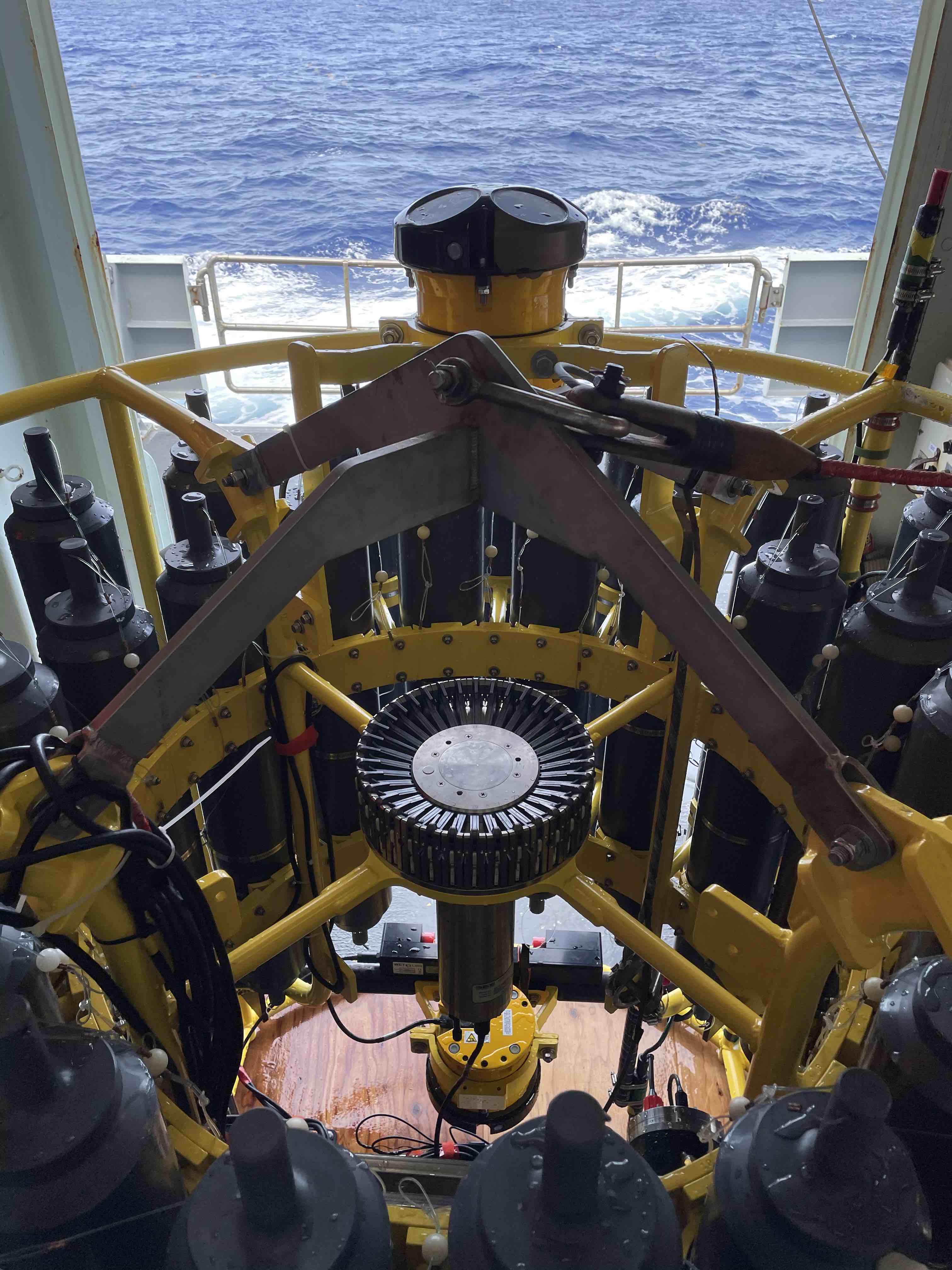

CTDO/rosette/LADCP/chipod casts were performed with a package consisting of a 36 bottle rosette frame, a 36-place carousel and 36 Bullister style Niskin bottles with an absolute volume of 10.6L. Underwater electronic components primarily consisted of a SeaBird Electronics housing unit with Paroscientific pressure sensor with dual plumbed lines where each line has a pump, temperature sensor, conductivity sensor, and exhaust line. A SeaBird Electronics membrane oxygen sensor was mounted on the “primary” line. A reference thermometer, Rinko oxygen optode, transmissometer, chlorophyll-a fluorometer, and altimeter were also mounted on the rosette. Chipod and LADCP instruments were deployed with the CTD/rosette package and their use is outlined in sections of this document specific to their titled analysis.

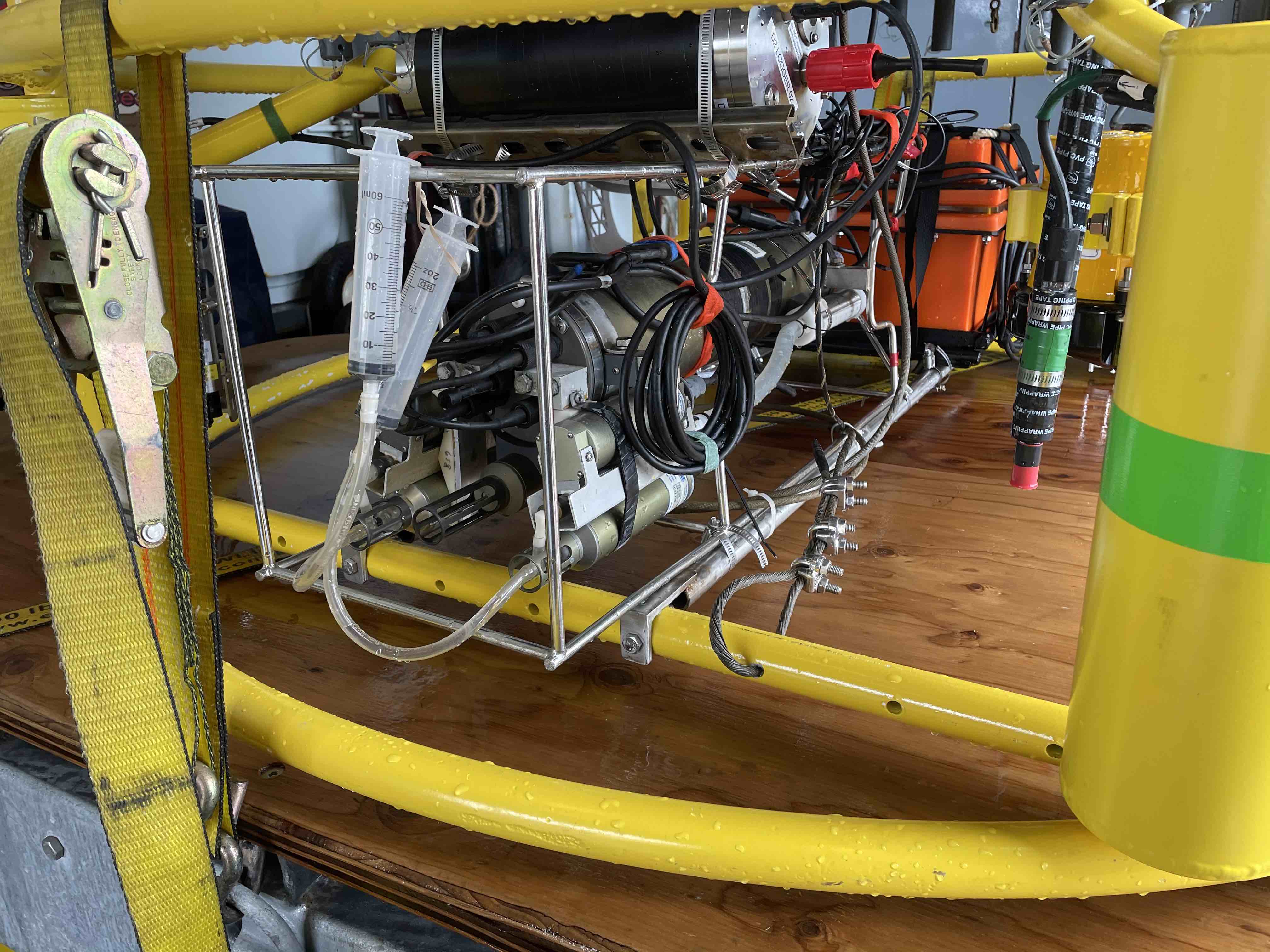

CTD and cage were horizontally mounted at the bottom of the rosette frame, located below the carousel for all stations. The temperature, conductivity, dissolved oxygen, respective pumps and exhaust tubing was mounted to the CTD and cage housing as recommended by SBE. The reference temperature sensor was mounted between the primary and secondary temperature sensors at the same level as the intake tubes for the exhaust lines. The transmissometer was mounted horizontally on the lower LADCP brace with hose clamps around both of its ends, avoiding shiny metal or black tape inside that would introduce noise in the signal. The oxygen optode, fluorometer, and altimeter were mounted vertically inside the bottom ring of the rosette frames, with nothing obstructing their line of sight. The 150 KHz bi-directional Broadband LADCP (RDI) unit was mounted vertically on the bottom side of the frame. The 150 Khz LADCP was later replaced with a 300 Khz LADCP during the cruise in the same position. The 300 KHz bi-directional Broadband LADCP (RDI) unit was mounted vertically on the top side of the frame. The LADCP battery pack was also mounted on the bottom of the frame. The LADCP and LADCP battery pack were mounted next to each other at the beginning of the cruise. If we imagine the LADCP battery being north on the rosette, the LADCP was mounted east, and the CTD mounted south.

Equipment |

Model |

S/N |

Cal Date |

Stations |

Group |

|---|---|---|---|---|---|

Rosette |

36-place |

Yellow |

– |

901-90 |

|

CTD |

SBE9+ |

0914 |

– |

901-90 |

|

Pressure Sensor |

Digiquartz |

110547 |

Feb 5, 2021 |

901-90 |

|

Primary Temperature |

SBE3+ |

32309 |

Feb 2, 2021 |

901-90 |

|

Primary Conductivity |

SBE4C |

43399 |

Nov 25, 2020 |

901-90 |

|

Primary Pump |

SBE5 |

51871 |

– |

901-90 |

|

Secondary Temperature |

SBE3+ |

32380 |

Feb 2, 2021 |

901-90 |

|

Secondary Conductivity |

SBE4C |

41880 |

Dec 4, 2020 |

901-90 |

|

Secondary Pump |

SBE5 |

58690 |

– |

901-90 |

|

Transmissometer |

Cstar |

1803DR |

Aug 9, 2019 |

901-90 |

|

Fluorometer Chlorophyll |

WetLabs ECO-FL-RTD |

1156 |

– |

901-90 |

|

Primary Dissolved Oxygen |

SBE43 |

431138 |

Dec 5, 2020 |

901 |

|

Primary Dissolved Oxygen |

SBE43 |

430275 |

Nov 14, 2020 |

1-14 |

|

Primary Dissolved Oxygen |

SBE43 |

430255 |

Nov 13, 2020 |

15-90 |

|

Oxygen Optode |

JFE Advantech RINKO-III |

0297 |

April 7, 2017 |

901-35, 41-46 |

|

Oxygen Optode |

JFE Advantech RINKO-III |

0296 |

April 7, 2017 |

36-90 |

|

Reference Temperature |

SBE35 |

0105 |

Feb 9, 2021 |

901-90 |

|

Carousel |

SBE32 |

1178 |

– |

901-14 |

|

Carousel |

SBE32 |

0187 |

– |

15-90 |

|

Altimeter |

Valeport 500 |

59116 |

– |

901-15 |

|

Altimeter |

Valeport 500 |

53821 |

– |

16-36, 39-90 |

|

Altimeter |

Valeport 500 |

67356 |

– |

37 |

|

Altimeter |

Valeport 500 |

67355 |

– |

38 |

|

DL LADCP |

Teledyne RDI WH150 |

19394 |

– |

1-17, 35-40 |

|

DL LADCP |

Teledyne RDI WH300 |

24497 |

– |

18-31, 40-90 |

|

DL LADCP |

Nortek Signature100 |

– |

– |

901, 32-34 |

|

UL LADCP |

Teledyne RDI WH300 |

12734 |

– |

901-90 |

|

D2 CTD |

D2 CTD |

02-1564 |

– |

901-36 |

|

D2 CTD |

D2 CTD |

02-1563 |

– |

37-90 |

|

Chipods |

Chipod |

2018 Ti44-2 |

– |

901-90 |

|

Chipods |

Chipod |

2024 Ti44-7 |

– |

901-90 |

|

Chipods |

Chipod |

2032 Ti44-15 |

– |

901-90 |

Package sensor looking into the rosette from the south.¶

Package sensor setup from east.¶

Package sensor setup from north.¶

From left to right: oxygen optode, fluorometer, LADCP battery pack, altimeter.¶

Package setup from southwest, with CTD in foreground and downlooking chipod to the right.¶

Packaget setup from west¶

Package setup from west, top view.¶

Winch and Deployment¶

The aft DESH-5 winch deployment system was used for all stations. The rosette system was suspended from a UNOLS-standard three-conductor 0.322” electro-mechanical sea cable. The sea cable was terminated at the beginning of A20-2021, electrical retermination after station 9, and full retermination after station 23.

The deck watch prepared the rosette 10-30 minutes prior to each cast. The bottles were cocked and all valves, vents, and lanyards were checked for proper orientation. Any biofouling noted was cleaned off the outside of the rosette before the next cast, and the inside of the bottles were checked for biofouling and sprayed down. LADCP technician would check for LADCP battery charge, prepare instrument for data acquisition, and disconnect cables. Once stopped on station, the Marine Technician would check the sea state prior to cast and decide if conditions were acceptable for deployment. The rosette was moved from the sampling bay out to the deck using the Thompson’s new winch-driven cart. Once on deck, the ratchet straps connecting the rosette to the cart were removed and sea cable slack was pulled up by the winch operator. CTD watch standers would then turn on the deckbox and begin data acquistion, and the cast would begin. Recovering the package at the end of the deployment was the reverse of launching. Once rolled back into the sampling bay, the ship crew secured the cart to the deck using additional ratchet straps. The carousel was rinsed and sensors were cleaned (as described below) after every cast, and then samplers were allowed to begin collecting water.

Maintenance and Calibrations¶

During A20-2021 routine maintenance was done to the rosette to ensure quality of the science done. Actions taken included rinsing all electrical instruments on the rosette down with fresh water after each cast and adjusting hose clamps and guide rings as needed such that lanyards had appropriate tension. Care was taken not to rinse the spigots and other parts of the bottle that might be touched by samplers in order to not contaminate the samples. After each cast, syringes of fresh water were connected to the plumbed lines to rinse the sensors and allow them to soak between casts. While in freezing conditions, water was drained after rinse to avoid freezing in the plumbing. Overhead heaters recently installed on the Thompson were run while in freezing or near-freezing conditions. The rosette was routinely examined for valve and o-ring leaks, which were maintained as needed. SBE35RT temperature data was routinely downloaded each day.

Every 20 stations, the transmissometer windows were cleaned and on deck blocked and un-blocked voltage readings were recorded prior to the cast. The transmissometer was also calibrated before the start and after the end of science operations.

Logs¶

In port: Preparation of the CTD and rosette took all but the first day allocated in port, which was used for unloading the container and setting up the labs. Additional integrity checks on the rosette, such as checking lanyard angles, o-ring and lanyard replacement, and spigot movement waited until being underway to be checked as lower priority tasks. We are using a new mounting system for the downward looking LADCP which has the LADCP clamped facing inward instead of outward, which will cause problems if we need to change that LADCP in rough weather.

March 17, 2021

90101 – Test cast down to 1500 m in 2020 m water depth. SBE43 oxygen had noticeable near-surface spiking during both up and downcast. The sensor is suspected to have frozen and was replaced. Variable transmissometer data were observed at depth but were simply due to loose electrical tape flapping in front of the beam path.

March 21, 2021

No problems noted for stations 00101-00801.

March 22, 2021

00801 – No problems noted.

00901 – During upcast, bottle 31 did not receive firing confirmation. Attempted to manually fire from deck box but still did not receive any confirmation. Upcast continued as normal, stopping and “firing” bottles at target depths, but rosette was recovered with bottles 31-36 still open. Modulo errors started occuring after firing bottle 30, with 17 total errors at depth and 2 additional during recovery. The issue was found to be the electrical termination, which was done using butt connectors with low-temperature solder. The ground wire had a solid connection but the communcation wire connection separated after applying tension. Communcation wire was re-connected using regular solder.

01001 – Oxygen spike at ~2400 m.

March 23, 2021

01101 – SBE43 had normal behavior during downcast but erratic readings started in the upper 25 m during upcast.

01201 – SBE43 data were spiky during soak, even after pumps were activated. Spikiness continued while brought up to the surface before normalizing during the downcast. No more spikes occurred until 15 m from surface during upcast.

01301 – Similar to previous cast, spikiness was noted during soak and down to 70 m. Downcast data were fine but two large spikes occurred at ~1950 and ~160 m during upcast, with spikiness again occurring near-surface. All connections between 9+ and 43 were inspected and looked okay (no spikes occurred in altimeter, which shared a Y-cable with the SBE43). Straight cable from Y to SBE43 was replaced after cast. Bottle 12 did not close, bottle 36 fired on the fly.

01401 – SBE43 still spiky at surface and down to 80 m but “fuzziness” of signal at depth seems improved with new cable. Sensor 43-0275 was replaced with 43-0255, with the suspected issue being frozen sensor membrane. Bottle 12 did not close again. Carousel changed out, solenoid 12 was swollen.

01501 – New SBE43 data were significantly improved. Altimeter reading during bottom approach was “stuck” at 20 m for longer than reasonable, replaced S/N 59116 with 53821 after cast.

March 24, 2021

01601 – SBE43 oxygen “fuzziness” at depth has returned. New altimeter appears to be functioning properly.

01701 – Botle 36 fired on the fly.

01801 – Multibeam depth estimate and altimeter not in agreement, CTD got within 3 m of bottom. Multibeam software was updated with new soundspeed profile, continue to regulary update after subsequent casts. Heave compensation used after 400 m.

01901 – Bottle 28 closed itself on deck before deployment.

March 25, 2021

02001 – Strong Gulf Stream currents (2 m/s at surface), large wire angle and far drift expected.

02101 – No problems noted.

March 26, 2021

02201 – No problems noted.

02301 – During recovery, new AB was training on winch and mistakenly pulled wire in too fast and the Evergrip mechanical termination was pulled into the block and became stuck (two-blocked). Ship crew used a chain-fall and were able to safely pull the stuck termination from block. Log of tension data recorded a maximum of 11,000 lbs, above the nominal 10,000 lb breaking strength of the sea cable. 50 m of cable was removed and re-termination was done during transit to next station.

02401 – No problems noted.

March 27, 2021

02501 – No problems noted.

02601 – SeaSave failed to connect to water sampler, likely started software too soon after turning on deck box.

02701 – No problems noted.

02801 – No problems noted.

March 28, 2021

02901 – During deployment, tagline became tangled on rosette and CTD. Line was cut as rosette was mostly in the water. Recovered with tagline still badly tangled. Chipod S/N 2024 sensor tip poking out of its pressure case, both o-rings were exposed, and the interior was full of water. Entire sensor and housing were replaced prior to next cast.

03001 – No problems noted.

03101 – No problems noted.

March 29, 2021

03201 – No problems noted.

03301 – Erratic altimeter readings near bottom.

03401 – Erratic altimeter readings near bottom.

March 30, 2021

03501 – Erratic altimeter readings near bottom.

03601 – Rinko S/N 0297 was replaced with 0296 due to intermittent spiking during casts. Upon recovery, D2 S/N 1564 spit out oil, replaced with 1563 using same logger. Altimeter still erratic, replaced Valeport 500 S/N 53821 with TGT’s 67356.

03701 – Altimeter S/N 67356 failed (was already bad?), replaced with TGT’s 67355 which deck tested okay.

03801 – Altimeter was very noisy during bottom approach and then became completely unreliable, reading 99.9 m despite being near bottom. Cast was ended higher than normal to be safe, ~20 m. Swapped back to ODF altimeter S/N 53821. Bottle 2 closed at wrong depth, unclear if early or late.

April 1, 2021

04101 – Attached second Rinko (S/N 0297) in spare voltage channel, mounted behind the replacement (S/N 0296) to compare data signals. 0297 data are much more spiky than 0296, with voltages completely deviating on the upcast. End cap on 0297 may not have been removed prior to cast. Altimeter was spiky at bottom but reliable enough to get to 10 m from bottom.

04201 – Downlooking LADCP switched from 150 kHz to 300 kHz. Multibeam continuing to be unreliable, CTD was 40 m from bottom before watchstanders noticed. Proceeded to ~10 m from bottom, altimeter working much better. Suspected there was interference with 150 kHz possibly (though this has not been observed before by LADCP PI). Plumbing on secondary T/C line was loose after cast, replaced with spare/backup tubing.

04301 – Console “glitched” while attempting to fire bottle 30. Firing confirmation was not received and interface reset next bottle to be fired back to bottle 1. Students fired 1-6, assuming it was 31-36, at the appropriate depths, but upon recovery bottles 31-36 were open/unfired. Both the .bl file and reference thermometer have data recorded for 31-36. No recording for 30 despite bottle being closed upon recovery. SeaSave bottle firing settings updated to allow changing next bottle, instead of purely sequential.

April 2, 2021

04401 – No problems noted.

04501 – Bottle 2 likely closed at wrong depth, unclear if early or late. O2 analyst recorded temperatures for bottles 1-3 as 8.0, 15.5, and 8.3 ºC.

04601 – No problems noted.

April 3, 2021

04701 – No problems noted.

04801 – Bottle 2 likely closed at wrong depth, unclear if early or late. O2 analyst recorded temperatures for bottles 1-3 as 8.3, 14.6, and 9.0 ºC.

04901 – No problems noted.

05001 – No problems noted.

April 4, 2021

No problems noted for stations 05101–05301.

April 5, 2021

05401 – No problems noted.

05501 – Bottle 2 possibly closed at wrong depth, unclear if early or late. O2 analyst recorded temperatures for bottles 1-3 as 7.6, 8.0, and 7.8 ºC. Replaced the entire latch mechanism on the water sampler.

05601 – Bottle 10 did not close. During upcast NMEA time froze for several seconds, ended up being ship problem of interference with Iridium antenna (not a CTD problem).

05701 – No problems noted.

April 6, 2021

No problems noted for stations 05801–06101.

April 7, 2021

No problems noted for stations 06201–06501.

April 8, 2021

06601 – No problems noted.

06701 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

06801 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

April 9, 2021

06901 – Bottle 10 didn’t close, one chipod missing cap upon recovery.

07001 – No problems noted.

07101 – No problems noted.

April 10, 2021

07201 – Bottle 25 mistrip, temperatures for 24-26 were 14.5, 20.0, 15.8 ºC.

07301 – Bottle 2 mistrip again, temperatures 7.3, 23.2, and 8.0 ºC.

07401 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

07501 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

07601 – Getting bad SBE35RT readings in high gradient regions (16 ºC change over ~200 m). Waiting for 1 minute prior to firing when possible.

April 11, 2021

07701 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

07801 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

07901 – Fired bottles 1, 4, 3, 2, then normal (to avoid continually losing near-bottom depth, i.e., bottle 2).

08001 – Fired bottles 2 and 3 at same depth for the remaining casts to test for misfires (casts no longer deep enough to have 36 unique bottles).

08101 – No problems noted.

April 12, 2021

08201 – Primary T/C line had large spike on downcast, likely biofouling in plumbing which eventually flushed out. Using secondary line for this cast.

08301 – No problems noted.

08401 – No problems noted.

08501 – No problems noted.

08601 – Strong surface currents, drifting slightly.

08701 – Strong surface currents, drifting slightly.

08801 – Strong surface currents, drifting slightly.

08901 – Bottle 8 misfired/dry fired in air after recovery.

09001 – No problems noted.

Sensor Problems¶

Oxygen sensor spikiness: The SBE 43 oxygen sensor showed erratic spikiness that disappeared after the cast was below ~50-100 m, but returned in the same depth range on the upcast. The suspicion is that some/all of the sensors froze, either during transit or while sitting in port, partially damaging but not completely ruining the internal membrane. Under sufficient pressure, the issue “fixed” itself for the duration of the cast. After swapping to the second spare, the issue was resolved. Rinko optode data were also used as primary for station 36 onward.

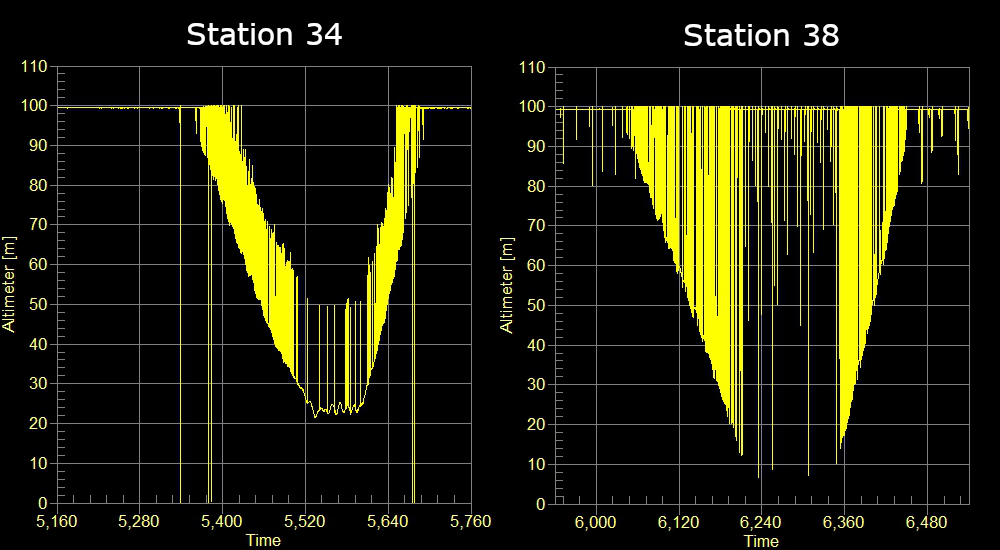

Altimeter spikiness: Four separate altimeters were used over the course of the cruise, two belonging to ODF and two belonging to TGT. The first ODF one flooded, the second was noisy. After trying the two owned by TGT, which were more noisy than the ODF spare, we swapped back. All altimeters were reporting spiky data, occasionally to the point of being unusable during the bottom approach (e.g. Fig 8, station 38). Additionally, multibeam depth estimates were inaccurate which caused further difficulty.

The multibeam issue was resolved by updating the sound speed profiles periodically to have a more reliable depth estimate. The altimeter issue was resolved after multiple changes to the rosette, including swapping downlooking ADCPs (from 150 KHz to 300 KHz) and adding additional rubber to increase the distance between the sensor and the unistrut mount. One suspicion was that the 150 KHz ADCP was interfering with the signal. It is also possible that the altimeter was not acoustically decoupled from the frame and was ringing with the ADCP frequency output. The downlooking ADCP was swapped multiple times (see ADCP section) during this time period so it is difficult to isolate exactly which solution was most important.

Altimeter readings during bottom approach on stations 34 and 38.¶

Bottle mistrips: Throughout the cruise, guide rings had to regularly be raised up to ensure the bottle ends caps were could not close themselves before being fired. Water sampler latches failed to release multiple times, with bottles coming to the surface still latched open despite being “fired.” Entire water sampler/carousel was replaced after station 14 due to a swollen solenoid inhibiting bottle firing.